MANGO COMMITTED SPRING 2019

The world is undergoing a process of change and so is Mango. The firm has introduced new techniques in the production of its SS19 season jeans and managed to reduce water consumption by up to 10 litres per garment. For models such as Boy and Straight, water consumption has been decreased by up to 16.5 litres.

In its ongoing pledge to environmentally-committed fashion, Mango analysed the water footprint (the volume of water used in production) of a standard pair of its jeans and detected that cotton production and finishing processes account for 90% of water consumption.

The company, in collaboration with experts in the field, has therefore developed two initiatives. The introduction of ECOWASH technology, by the company Jeanologia, has helped to reduce the consumption of water, energy and chemicals. The incorporation of the Better Cotton Initiative (BCI) in garments also encourages the use of sustainable cotton farming techniques, reduces the consumption of water and chemicals and guarantees workers’ health and safety. Organic cotton, which reduces water consumption during cultivation, and recycled cotton, which encourages a circular economy, are likewise used.

The implementation of these improvements means that 38% of the SS19 jeans collection has sustainable characteristics. For the forthcoming AW2019 season, over half the production of Mango jeans is expected to be sustainable.

MANGO Committed

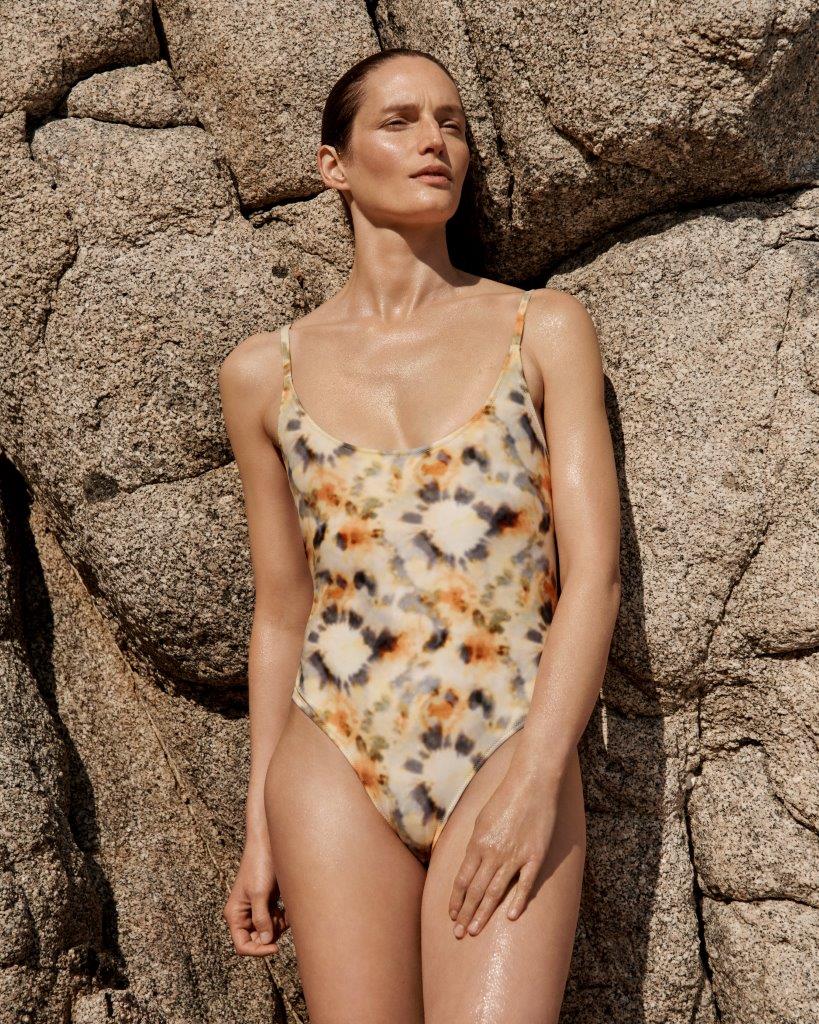

The firm is launching the new Mango Committed collection, a selection of environmentally-committed designs. Mango has been using recycled fabrics and sustainable fibres in designing this capsule of garments since 2017.

Simple lines and a range of soft colours define the aesthetics of these pieces, which have been made using fabrics such as viscose and organic cotton. The printing of dresses and flowing jumpsuits enhances the collection’s special character as it is inspired by nature.

The SS19 Committed collection has also been created with BCI certified cotton and new technologies and sustainable fibres. LENZING REFIBRA has created GREENCEL, a 100% natural biodegradable fibre sourced from trees and whose manufacture does not use toxic compounds, and the new TENCELä Lyocell, a fibre created with off-cuts of cotton originating from other manufacturing processes and wood cellulose. By using environmentally-friendly fibres, we can reduce the impact on the Planet.